Campaign 2-2 Update, and Our Journey Through Flight Test

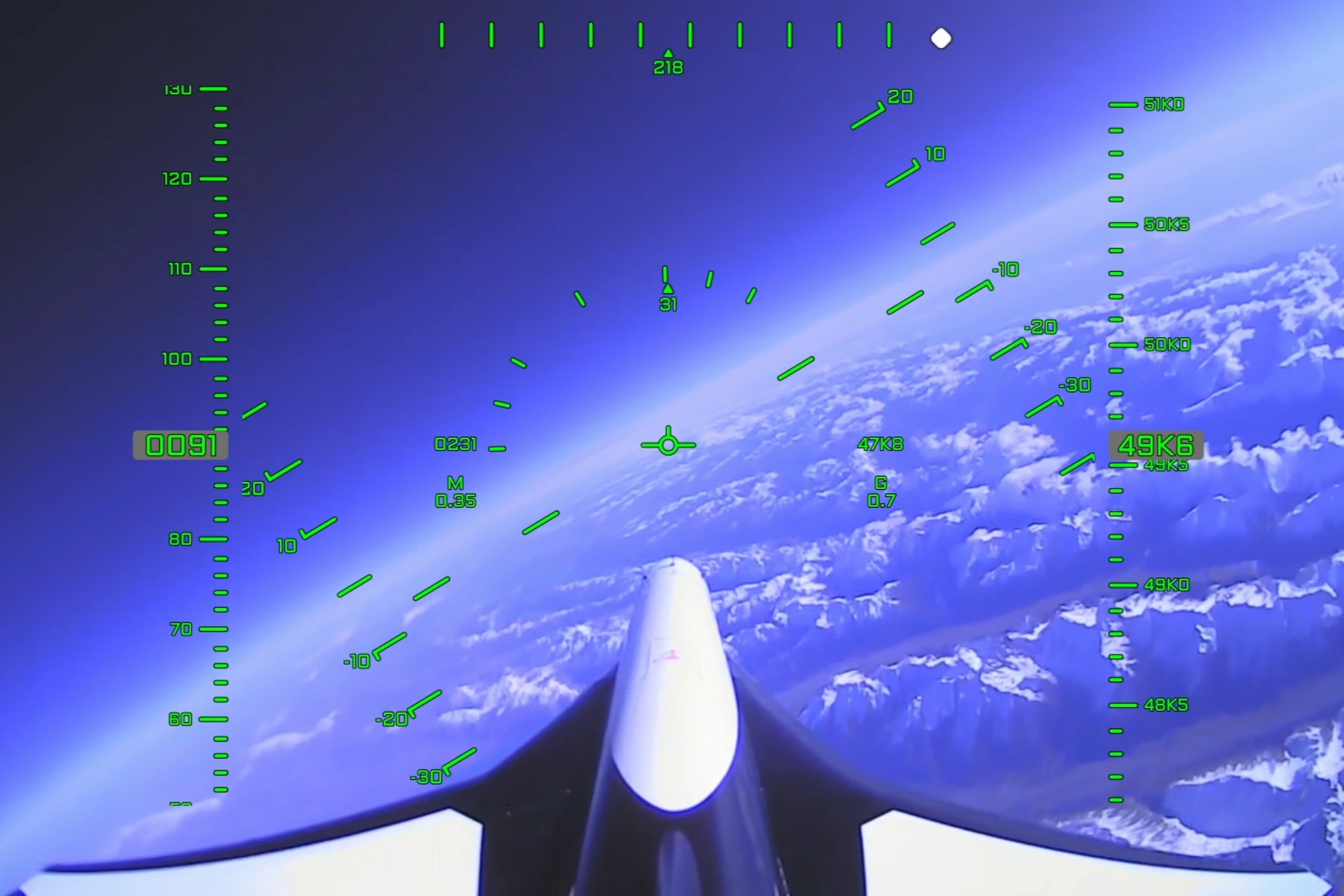

Mk-II Aurora at 50,000 ft, July 2024 from Glentanner Aerodrome, New Zealand.

Date: 7 August 2024

Location: Christchurch, New Zealand

Today we are announcing the completion of another flight test campaign of our Mk-II rocket-powered aircraft The campaign (dubbed Campaign 2-2) saw three flights completed in late July. In flight three, we achieved a maximum speed and altitude of Mach 0.92 (967 km/h) and 50,000ft (15.1km). That is 3x and 5x of what we had achieved in the previous campaign – a massive jump in demonstrated performance.

We are now poised to fly supersonic in Campaign 2-3, scheduled for September. But that is just the beginning. In many respects, the Mk-II is slated to be the highest-performance vehicle to take off from a runway.

By the end of 2025, we’re looking to

climb faster than an F15,

fly higher than a Mig 25,

faster than an SR-71, and,

ultimately, be the first vehicle to fly above the Karman line; 100km altitude (the generally accepted definition of “space”), twice in a single day.

Some of these records have stood for over 50 years.

We have spent about $10 million USD on the program to date, and plan to complete it for under $20 million total. So why do we think we will be able to achieve such high performance, with such modest investment? And how are we able to progress through flight testing so quickly compared to other rocket development programs?

The secret lies in the core philosophy and resultant design and test methodology. It’s a philosophy that empowers us to move quickly, yet confidently through flight test, pushing the envelope with each flight while taking on minimal risk. It’s our secret sauce, except it’s not a secret.

Philosophy – an aircraft with the performance of a rocket, not a rocket with wings.

Four of the five Dawn founders came from the world of traditional rockets. We built some awesome tech that went high and fast, for a few minutes. And then, even if it had worked perfectly, it was scrap.

The other founder, my brother, James, had worked on aircraft. It was still awesome and high-performance stuff, but designed to work all day, every day. They are the workhorses of our everyday lives delivering thousands of tons people and cargo all over the world.

It was 2017. We could see SpaceX making fantastic progress retrofitting reusability into the first stage Falcon 9. And they were looking at full reusability with Starship. But we didn’t want to follow that same path because of the extreme capital cost and lack of market opportunity until full performance is reached. We didn’t have the deep pockets of Elon or our American VC-funded counterparts.

From day one, we knew we wanted the properties of an aircraft in the final product – rapid reusability, high reliability, and ultimately, extremely low marginal cost of operation which will unlock whole new business models for our future customers. But we wanted to maintain those properties right through the flight test program too. High flight cadence means rapid testing, iteration, and learning which is the lifeblood of any tech company.

At each major performance increase, we would have splinter products to cater to the many markets along the way; high-altitude atmospheric research, microgravity, hypersonics, pseudo-satellite earth observation, and ISR to name a few. Each step could help to fund the next.

If you plot a graph of reusability (Y-axis) vs performance (X-axis), as shown below, Dawn would start at the top left; “low performance, highly reusable”. With each test and each vehicle, we would move to the right, increasing performance, and maybe increasing test cadence a little too. This is similar to how many other types of aircraft are developed, and distinctly different from traditional rockets, even those with wings such as the Shuttle.

Traditional rockets are nearly totally useless until they reach orbital performance because they are prohibitively expensive to service any suborbital or point-to-point market. Even well-funded defense markets like hypersonics are a stretch. Once operational, if they want to shoehorn in reusability or usually more commonly “refurbishability”, it comes at a large performance cost, often 30-50% of payload capability. Once again, despite SpaceX’s success in walking this path, it was not one we wanted to follow.

Back to aircraft…

As a result of this desire to be an aircraft, every design decision made had to maintain the essential properties of an aircraft – a vehicle that uses standard runways, established scalable regulation, engines that use storable propellant, can start, stop and throttle at will, and with turnaround times you would expect from any other aircraft.

Beyond the technology itself, it was essential that we certify as an aircraft. This would allow general one-time licensing in nonexclusive airspace, rather than flight-specific licenses that need to be obtained for every flight. This drove the design standard of the vehicle up and meant we included redundancy in critical systems such as avionics, communications, and control surfaces.

An aircraft standard is a hard standard to achieve, but once there, unlocks the development path that brought aircraft from the Wright Brothers’ first flight to transatlantic jets in just 55 years.

In short, we realized we were building aircraft with the performance of a rocket, not a rocket with wings.

Flying as an aircraft allows us to take many small risks in quick succession, rather than all the risks at once. We can be measured and considerate between tests, always adjusting the steps we are taking to keep the risk at an appropriate level. We can be precise about that level of risk because we are working with high-fidelity flight test data, rather than relying on simulations or wind tunnels alone. We can do it for real.

We learn about hard problems, incredibly quickly and with minimal cost.

This philosophy has saved us from thousands of hours of paralysis by analysis, countless inflight issues, and years of rebuilding vehicles. We will never go back.

Development paths of different vehicle types.

Our Flight Test Journey So Far

Our mission is to bring scalable, sustainable space transportation to the world. We started with in-space transportation by redesigning the fuels for satellites, and now in-space refueling. That business is profitable and growing.

Redesigning space launch is somewhat more challenging due to the sheer performance required to get to orbit. History shows that new rockets take decades to develop when traditional methods are used.

Hence, the early stage of the journey focuses not on the performance required to achieve the end mission, but on establishing methods and fundamental technologies needed to learn faster or at least more efficiently than anyone else. This will be the muscle that will get us there faster in the long run.

Dawn Aerospace rocket-powered aircraft development timeline.

Mk-I

Objective: Prove that we could build a rocket engine that was as pilotable and reusable as a jet engine. Performance did not matter.

Secondary objective: Prove we were not just kids in a garage, rather, we were reasonably capable kids in a garage, deserving of modest funding.

This project was a great learning experience for us as a young company, but also a great chance to show that there is nothing crazy about rockets that makes them less useable and reuseable as a jet engine i.e. stop and start as needed, no toxic propellants or igniter fluids, high reliability, maintainable – nothing that invalidated it being a true “aircraft” in the common sense of the word.

We completed the project with a surrogate model jet airframe and a custom-designed pressure-fed, 3D-printed bipropellant engine using propellants - nitrous oxide and propene - which we were already familiar with from our satellite propulsion work.

The original engine print worked flawlessly the first time and the aircraft flew beautifully. We never had to print a second engine.

Performance was never the goal, and the airframe wasn’t designed to take the power of the engine. Even in steep ascending flight, it would accelerate too fast, and we would shut down prematurely to avoid risking the aircraft. It was a lot of fun!

Mk-I - Static test

Mk-I - In flight

The Mk-II Aurora Program

Objective: Bring the performance of a rocket to a rapidly reusable aircraft platform. Specifically:

>3km/s total delta V of performance and thus be able to fly a trajectory typical of a rocket first stage, and

be able to repeat the feat twice in one day.

Secondary objective: be the first vehicle to fly to above the Karman line (100km) twice in a day.

This was the first “clean sheet” aircraft design for Dawn and intended to demonstrate what “an aircraft with the performance of a rocket” really means. This vehicle should smash all existing records for traditional (not air launched) aircraft. It was a big goal for a small vehicle, but we first had to prove it could fly at all!

Mk-IIA – Jet

Several campaigns conducted, 47 flights total between July 2021 and August 2022.

Objective: Prove the aircraft, operations and regulation, minus the engine, worked.

The first Mk-II vehicle, the “Mk-IIA”, was designed to accept both jet and rocket engines (separately) and was over-designed as a “battleship” test aircraft.

We conducted 47 flights using surrogate jet engines up to modest speeds of 200 knots and 9000ft. These flights taught us a lot about the vehicle at low subsonic speeds, <Mach0.3. Perhaps more importantly, it provided a low-risk training ground where we could design, simulate, build, certify, and operate an aircraft. This was important for our own learning, but also for building trust with the regulator, New Zealand’s CAA, who are responsible for approval of our vehicle certification.

Some lessons we learned the hard way. A dual engine flame out at low altitude forced an improvised landing across the runway which collapsed the landing gear. In another flight, a brake failure on landing caused the vehicle to roll off the runway damaging the nose and right wing. In both cases, safety was never in question and the vehicle was repaired and improved. In a matter of weeks, we were out flying again, a little wiser than before.

These early tests, and failures, served their purpose of teasing out real-world problems at an early stage with minimal risk. The perfect demonstration of the usefulness of flying as an aircraft, not a rocket.

Mk-IIA - Jet, on the runway in Glentanner

Mk-IIA - Jet, in flight

Mk-IIA – Rocket Powered

Two campaigns conducted to date, six flights total.

Mk-IIA Objective: Fly supersonic to de-risk the Mk-II aerodynamic design.

Secondary objective: Demonstrate two flights in one day.

Once we could confidently operate the vehicle, it was time to remove the jets and fit the rocket engine.

This engine was still in development, but had passed a limited qualification, sufficient for short flights.

Campaign 2-1 consisted of three flights. We flew to moderate altitudes and speeds and altitudes of 200knots and 9000ft, similar to what we had achieved in jet power. This proved the vehicle could be successfully operated under rocket power and that aircraft like operations could be achieved.

This campaign went remarkably smoothly, despite so much new technology in the aircraft, although we had our fair share of curve balls.

A minor propellant leak on a low-pressure line from the first flight had to be resolved before the second. We uninstalled the engine and oxidizer tank, fixed the leak, and reassembled the aircraft. We flew 26 hours after the first flight. Once again, the philosophy of “being an aircraft” meant everything was designed to be maintainable and minor issues don’t spiral into major delays.

Weather closing in meant we could not complete a fourth flight, and what would have been the second of the day.

Campaign 2-2 was the first attempt to push the performance of the vehicle. We were incredibly excited to see what it could do, but still conscious of taking an iterative approach, expanding the envelope with each flight. Once again, three flights were conducted in three days.

In flight 3, we were able to achieve a maximum speed and altitude of Mach 0.92 (967 km/h) and 50,000ft (15.1km). That is 3x and 5x respectively of what we had achieved in the previous campaign.

The vehicle performed beautifully across all three flights with no recorded issues in the early transonic regime. Although we once again had some minor issues with other hardware. All were covered by redundant systems and robust “knock it off” criteria to ensure safety.

A video link failure for a few minutes meant we flew on backup video for a short stint. An air data probe issue was backed up by GPS-derived speed and altitude. Once again, the aircraft philosophy of high levels of redundancy meant these minor issues could all be handled in stride.

We are not even close to reaching the potential of the Mk-IIA, but this was our first taste of what “an aircraft with the performance of a rocket” really means. The speed, the noise, the view of the sky turning black as the vehicle rapidly ascends, but also the almost disbelief when it rolls back into the hangar 20 minutes later. Doing it all again the next day seemed like science fiction in front of our own eyes, even if we had been working towards this since building the Mk-I.

Flight 53, takeoff

Flight 53, shortly after apogee

Flight 53, engine cam from 45,000ft with the runway in view

Flight 53 Right wing, inverted during a canopy roll at apogee

Flight 53 of the Mk-II Aurora Rocket Powered Aircraft. 25 July 2024.

Campaign 2-2 flight path visualization. Flights 50 (green), 51 (yellow) and 53 (red).

The Future…

Campaign 2-3

Is intended to be the last campaign of envelope expansion for the Mk-IIA. As a battleship airframe, it has limited propellant capacity and thus total performance. Nonetheless, it should comfortably get us through the sound barrier to complete the main objective of investigating the transonic regime, and thereby de-risking the Mk-IIB development.

Campaign 2-3 will include performance upgrades to reduce propellant residuals to less than 2 per cent. This is enabled by allowing the pumps to detect running dry and shutting down automatically. This modification also allows us to remove the bubble traps in the tanks, decreasing weight and substantially reducing unusable propellant.

A slight increase in O/F ratio from 5.5 to 5.9 further increases Isp and thrust about 2%, and an injector optimization will increase thrust a further 8%.

Overall, we should have a 30% increase in total impulse, and 10% higher thrust over campaign 2-2, with 4.5kg (3.5%) less dry mass. It’s very satisfying to see the vehicle get better with each campaign.

Mk-IIB Aircraft

Objective: Complete the overall program objective of being the first vehicle to fly to space (100km altitude) twice in a day.

The Mk-IIB will be an optimized version of the Mk-IIA. With wingbox tanks, a 30% higher thrust engine, optimized structure, but identical outer shell, it will have dramatically more performance. With the inclusion of RCS thrusters, the Mk-IIB will be ready for flight far outside of the practical atmosphere.

The design of the Mk-IIB is well-progressed, and much of the component development has been de-risked through the Mk-IIA. We expect to start construction before the end of 2024 and begin flying in mid-2025, breaking records for speed and altitude as we go.

Beyond the Mk-II

The Mk-II is just a taste of what “an aircraft with the performance of a rocket” can do. 3km/s, Mach 3.5, and 100km altitude were almost arbitrary design requirements we can adapt to meet specific market needs.

We see two main development streams:

A higher payload capacity booster for microgravity / high altitude atmospheric research and Earth observation. This leads to our original mission of a TSTO orbital vehicle.

A vehicle optimized for high-speed flight in the atmosphere – hypersonic engine/materials/vehicle research, point-to-point transportation and defense.

We are seeing strong commercial traction in both streams across a wide range of users. I expect we will be flying the first payloads to moderate altitudes on the Mk-IIA before the end of this year, and many more with the Mk-IIB in 2025 and 2026. Commercial traction will help inform the next vehicle development decisions.

Regardless of the direction we take, the Mk-II program gives us an unmatched foundation in technology, methods, and team. From that unique position, we are poised to learn, build, and fly faster than ever before.

- Stefan Powell, CEO

Campaign 2-2 Crew

GALLERY