GREEN PROPULSION FOR ANY SATELLITE

Turn-key propulsion systems for 30 kg to 500+ kg satellites. Through standardised interfaces and flexible form factors, we deliver purpose-built systems — fast.

All systems include thrusters, tanks, valves, instruments, and control electronics. We’re a full-service partner, working with you wherever you need us, from initial design to on-orbit commissioning and operations.

Benefits of Chemical Propulsion

High thrust

Lower power

Modular

Scalable - 30 kg to 500+ kg satellites

-

Physical

Turn-key systems

All systems include thrusters, tanks, tubing, health monitoring, control electronics, and structuresPropellants

Nitrous oxide (N2O)

Propylene (C3H6)Pressurization

Self-pressurising. Propellants are stored as liquified gases under their vapor pressureForm factor

Standardised interfaces, flexible form factors. Adjust to volume, layout, and keep-out zone requirementsThrusters

Select QTY and thrust class(es). All connect to the same tank and control systems. Operate together or independentlyTank options

Type 1: All metallic. 3D printed using Inconel or Titanium

Type 3: Metallic liner with full, wound carbon-epoxy overwrap

Additional SpecificationsEnvironmental

Operational temperature

23°F to 86°F (-5°C to 30°C)Survival temperature

-22°F to 104°F (-30°C to 40°C)Regulatory

ITAR free and REACH compliantLauncher compliance

SpaceX Payload (Oct 2022) user’s guide. Please enquire for all other launchersPerformance

Total impulse

5,000 to 500,000+ N.s

Scalable in size and configurationThrust range

0.46 to 1.28 N (0.11 to 0.30 lbf) per B1 thruster

6.1 to 16.7 N (1.37 to 3.75 lbf) per B20 thrusterIsp, vac

250 to 280 s

Depending on system-level configurationInterfaces

Data

CAN bus, RS-485, or RS-422Supply voltage

Digital: 5.0 to 5.20 VDC

Actuators: 24.50 to 33.20 VDCServices

Full-service list

Off-the-Shelf or Customised Systems

Work with our engineers to create a custom system tailored to your requirements or leverage our extensive mission heritage by selecting a standardized design.

Reduced non-recurring engineering. Reduced costs. Reduced lead times.

Standard lead time: 6 months for recurring systems.

SD5 - 5kNs Class SatDrive

SD7 - 7kNs Class SatDrive

-

Total impulse - 5,000 N.s

Mass - 5 kg (dry), 7.5 kg (wet)

Volume (adjustable) - 36 x 31 x 15 cm

Variations - Two Completed -

Thrusters: 4x B1 thrusters

Tanks (Type 1 - Inconel): 1x Oxidizer, 1x Fuel

-

Total impulse - 7,600 N.s

Mass - 7 kg (dry), 11 kg (wet)

Volume (adjustable) - 87 x 42 x 10 cm

Variations - One Completed -

Thrusters: 1x B1 thrusters

Tanks (Type 1 - Inconel): 3x Oxidizer, 1x Fuel

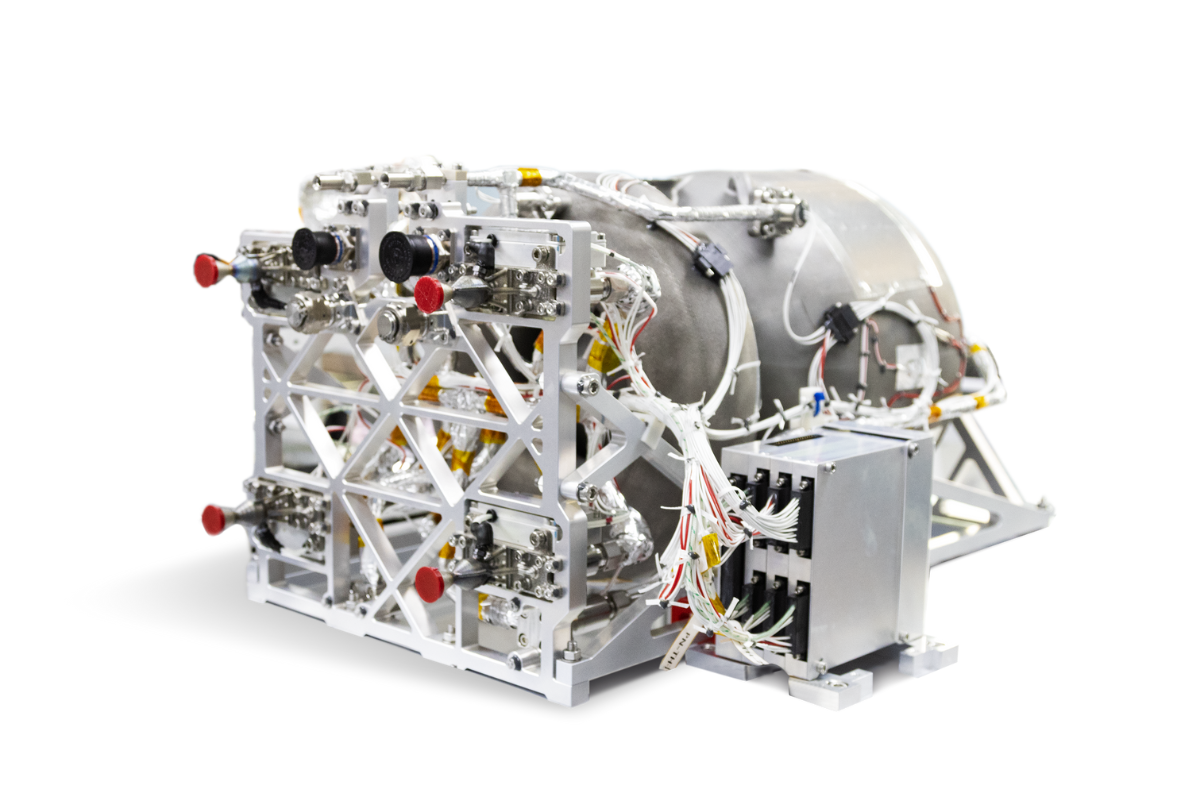

SD70 - 70kNs Class SatDrive

SD15 - 15kNs Class SatDrive

-

Total impulse - 70,000 N.s

Mass - 20 kg (dry), 50 kg (wet)

Volume (adjustable) - 70 x 70 x 48 cm

Variations - Two Completed -

Thrusters: 5x B20 thrusters

Tanks (Type 1 - Titanium): 4x Oxidizer, 4x Fuel

-

Total impulse - 14,500 N.s

Mass - 11.3 kg (dry), 17.7 kg (wet)

Volume (adjustable) - 27 x 25 x 45 cm

Variations - One Completed

Further variations available - contact us. -

Thrusters: 4x B1 thrusters

Tanks (Type 1 - Inconel): 1x Oxidizer, 1x Fuel

Nodes: 1 Controller, 6 Peripheral

Frame: In-house design. Easy bolt-on style for customer.

Custom Systems

-

Customize to achieve:

Dedicated impulse performance (within volume constraint, as possible)

Dedicated control authority

Dedicated thrust performance

-

Thrusters

Tanks

Nodes

-

Standard lead time: 6-18months

See our building block methodology below enabled by additive manufacturing, in-house technological capabilities and in-house testing facilities.

Dawn’s Green Propulsion Heritage

17

Satellites

3

Launchers

82

Thrusters

2

Thrust classes

Customers and Missions

"We are moving fast, and we need suppliers that can match our cadence and quality. The in-space heritage, creative thinking and solutions-focused approach we've seen from Dawn give us great confidence in their ability to deliver."

— Stephen Steg, CEO, Blue Canyon Technologies

Modular SatDrive Systems - How it Works

Dawn’s range of standardized components are assembled into various form factors to meet your mission requirements.

Plug-and-Play Components

-

Our core building block.

1N + 20N components, scaled together to offer a wide range of possible thrust configurations.B20 (20N bipropellant) & B1 (1N bipropellant) thruster).

Learn More -

Our fully standardised thrusters can be grouped and arranged to meet different requirements but cannot be customised.

Learn more about our thrusters

-

We offer teardrop, toroidal, and capsule tanks.

Additively manufactured in inconel or titanium in various sizes.

Composite tanks currently in development for larger sizes.

OptionsType 1:

All metallic. 3D printed Inconel or TitaniumType 3: Metallic liner with full, wound carbon-epoxy overwrap

Propellant storage

Stored separately. No pre-mixed propellants.Pressurization

Self-pressurisingValves

Pressure relief valves on tanksHeaters

Polyimide flexible heaters on each tank and feedline. -

We have standardised our design and qualification process for tanks meaning customisation is possible with minimal NRE time.

Size range

0.8L - 10L

Larger sizes in development

-

Modular control electronics design utilizes a main controller node to interface with the satellite, and downstream nodes for subsystems.

This ensures the interface between the propulsion module and satellite is kept constant, even when the propulsion module design changes in successive generations.

Interfaces

Data

CAN bus, RS-485 or RS-422Power

5.0 to 5.20 VDC (Digital/logic supply rail)24.50 to 33.20 VDC (Actuator supply rail)Engineering model / flatsat

Represents power, data, and software interfaces for HIL testing -

Modular components can be scaled up or down for different system sizes.

-

In-house configured to meet your requirements.

-

Feed Lines

Valves

Software

CubeSat propulsion systems and bolt-on collision avoidance kits for ESPA-class satellites. Each CubeDrive includes a B1 thruster, tanks, valves, and control electronics. Structures are 3D printed as a single monolithic piece using Inconel, including fuel and oxidizer tanks. Health monitoring instrumentation includes various thermocouples and pressure sensors.

-

Status

In spaceThruster

One B1 thrusterTotal impulse

402.5 Ns

90.5 lbf.sMass (dry / wet)

1080 g / 1275 g

2.38 lbm / 2.81 lbmDimensions

80 x 96 x 96 mm

3.15 x 3.78 x 3.78 inPropellants

Nitrous oxide (N2O) and

Propylene (C3H6)Tank type

Type 1: All metallic, 3D printedData

CAN busSupply voltage

Digital: 5 to 5.2 VDC, and

Actuators: 12 VDC unregulatedOperational temperature

-5°C to 30°C (23°F to 86°F)Survival temperature

-30°C to 40°C (-22°F to 104°F)

-

Status

In developmentThruster

One B1 thrusterTotal impulse (~)

1450 N.s

325 lbfsMass (dry / wet)

2050 g / 2700 g

4.52 lbm / 5.95 lbmDimensions

200 x 96 x 96 mm

7.87 x 3.78 x 3.78 inPropellants

Nitrous oxide (N2O)

Propylene (C3H6)Tanks

Type 1: All metallic, 3D printedData

CAN busSupply voltage

Digital: 5 to 5.2 VDC, and

Actuators: 12 VDC unregulatedOperational temperature

-5°C to 30°C (23°F to 86°F)Survival temperature

-30°C to 40°C (-22°F to 104°F)

Thrusters

Our standardised thrusters for scalable, modular SatDrive systems.

- 20N

-

The B20 thruster assembly includes the thruster body, valves, and control electronics.

The thruster body is additively manufactured as a single structure using Inconel 718 and includes the injector, combustion chamber, and nozzle. Isolation valves are included upstream of the firing valves for added redundancy.

Health monitoring instrumentation includes an integrated and isolated thermocouple and chamber pressure sensor.

With standard data and power interfaces, thrusters are easy to command and operate.

The B20 is also operable under ambient conditions to enable fast turnaround ground testing.

-

Physical

Thruster dimensions

176 x 80 x 79 mm

6.93 x 3.15 x 3.11 inDry mass

600 g

1.32 lbmNozzle expansion ratio

100:1Valves

Normally-closed solenoid

Four per thruster (firing and isolation)Interfaces

Mounting

3x M5 threaded holesPerformance

Thrust, range

6.1 to 16.7 N (1.37 to 3.75 lbf)Minimum impulse bit

Bi-prop: 1 N.s (0.22 lbf.s)

Cold-gas: 50 mN.s (0.01 lbf.s)Ignition

Spark-based igniterPulse frequency

4 HzRestarts

11,000+ per thrusterControl

Operable together or independently

Select your desired quantity

Pair with B1 thrusters.Firing modes

Bi-prop & cold-gas. Switch at will. Managed by not engaging the spark-ignitor.Cold-start capable

Yes. Highly repeatable -

Download PDF and STEP files here.

- 1N

-

Available in various form factors, the B1 thruster is currently utilized as the central thruster in Dawn’s CubeDrive propulsion modules and as a modular building block within Dawn's turn-key SatDrive systems. They can be positioned throughout the spacecraft, in clusters, and at various cant angles.

The B1’s assembly includes the thruster body, valves, and control electronics.

Thruster bodies are additively manufactured as a single structure using Inconel 718 and include the injector, combustion chamber, and nozzle.

Health monitoring instrumentation includes an integrated and isolated thermocouple and chamber pressure sensor. With standard data and power interfaces, thrusters are easy to command and operate.

-

Physical

Thruster dimensions

108 x 79 x 40 mm

4.25 x 3.11 x 1.58 inDry mass

260 g

0.57 lbmNozzle expansion ratio

100:1Valves

Normally-closed solenoid

Two per thrusterInterfaces

Mounting

4x 3.2mm holes.Performance

Thrust, range

0.49 to 1.35 N (0.11 to 0.30 lbf)Minimum impulse bit

Bi-prop: 74 mN.s (0.016 lbf.s)

Cold-gas: 1.4 mN.s (3.1e-4 lbf.s)Ignition

Spark-based igniterPulse frequency

4 HzRestarts

18,000+ per thrusterControl

Operable together or independently

Select your desired quantity

Pair with B20 thrustersFiring modes

Bi-prop & cold-gas. Switch at will. Managed by not engaging the spark-igniterCold-start capable

Yes. Highly repeatable -

DEFINING FEATURES

High-performance propulsion

Experience significant time and power savings by switching to spark-based ignition, allowing you to conduct cold-start to full thrust firings in under 100ms. Achieve high performance exactly when needed by removing sensitive catalysts.

Rideshare friendly

Dawn’s propulsion systems have flown on every SpaceX Transporter mission to date, Starlink rideshare, and Arianespace’s Vega rideshare. Learn more about our safe failure modes and why launchers like what we’re building.

A unified architecture

All Dawn systems use the same highly scalable N2O/C3H6 architecture. Select your desired thruster quantity and thrust class(es), tank size, and interface, then let us do the rest.

Less parts = higher reliability

Propellants are self-pressurising and don't require external pressurants, high-pressure regulators, or mechanical PMDs. There are no rare-Earth materials, catalyst beds, or proprietary propellants. The result: low part count, low weight, low cost, and high reliability.

Dual firing modes

Unique for rendezvous and proximity operations, all thrusters can operate in both a bi-propellant and cold-gas mode by controlling the spark igniter. Even with large thrusters, achieve tiny impulse bits for RPO, fine pointing, and servicing.

Domestic propellant suppliers

N2O (purity class 2.0) and C3H6 (purity class 2.5) are widely available from domestic suppliers. ITAR-free and REACH-compliant, avoid the international supply chain, export control, and cost issues of proprietary propellant blends.

“We are excited to partner with Dawn Aerospace on this important feature for our LizzieSat™ constellation. We believe Dawn’s turnkey propulsion technology will allow us to extend our time in orbit and deliver on our future value proposition of providing space-based data to a multitude of industries.”

— Carol Craig, CEO & Founder, Sidus Space

"With their series of space-proven components, Dawn's modular system is designed to grow as we grow. They have all the building blocks and thrust levels we need, allowing us to scale systems as needed, up or down."

— Andrés Villa, CTO, UARX Space

“We’re proud to utilize Dawn’s propulsion system on our mission to provide the world’s best hyperspectral Earth-imaging satellites. Our goal is to launch a constellation that acts as a global health monitor for the planet. With Dawn’s help, we’re one step closer to achieving that and build a healthier planet.”

— Awais Ahmed, CEO & Co-founder, Pixxel

DESIGN, DELIVERY, & SUPPORT 🚀

Mission design

Whether you want orbit insertion, phasing, stationkeeping, debris avoidance, life extension, momentum management, de-orbiting, or all the above, we’ll help you with mission success.

Engineering support

Although our systems all use a unified architecture, we know that satellite builders have different needs. That’s why we give engineering support to all our customers.

Production

High-volume and high-cadence production. State-of-the-art additive manufacturing with lean production methodology. In-house 5-axis machinery and cleanrooms.

Accelerated schedules

Enabled by vertically integrated capabilities of engineering, manufacturing, and testing.

Environmental qualification

In-house hot-fire and hydrostatic test facilities. Access to world-class test facilities for thermal cycling, shock, 3-axis vibration, and radiation testing.

Acceptance testing

In-house vacuum chambers and ambient test setups for hot-fire and full hardware-in-the-loop tests. Standardized and well-defined test procedures and quality assurance plans.

Export

Global export licenses, exporting from New Zealand and The Netherlands. Flown on satellites launched aboard 🇺🇸 and 🇪🇺 vehicles.

Launch-site fueling support

Dawn provides worldwide support for satellite fueling and propellant sourcing, whether at the launch site or your own premises.

On-orbit commissioning

We don’t just deliver you hardware, a few ICDs, then leave you to it. We are a full-service partner by your side the entire way.